Product description:

Forged Carbon Fiber Sheet is a manufacturing process that involves heating a mixture of carbon fiber and resin to a high temperature and forming the desired shape of the board through pressure and mold. The following are the general steps for forging Carbon Fiber board:

1. Preparation of materials: Prepare a mixture of carbon fiber and resin, ensuring that their proportions are appropriate.

2. Heating: Place the mixture in a heating furnace and heat it to a high temperature to melt the resin.

3. Pressure: Place the heated mixture into the mold and apply pressure. Pressure helps to form the desired sheet shape and ensures that the resin fully penetrates the fibers.

4. Cooling: After the shape of the sheet stabilizes, remove it from the mold and let it cool. During the cooling process, the resin will solidify again.

5. Post treatment: According to needs, the board can be subjected to post treatment, such as trimming, polishing, and coating.

The specific parameters and steps for forging carbon fiber board may vary depending on the application and manufacturer. In addition, forging carbon fiber board is a professional technology that requires experience and professional equipment to ensure the production of high-quality Carbon Fiber Plate.

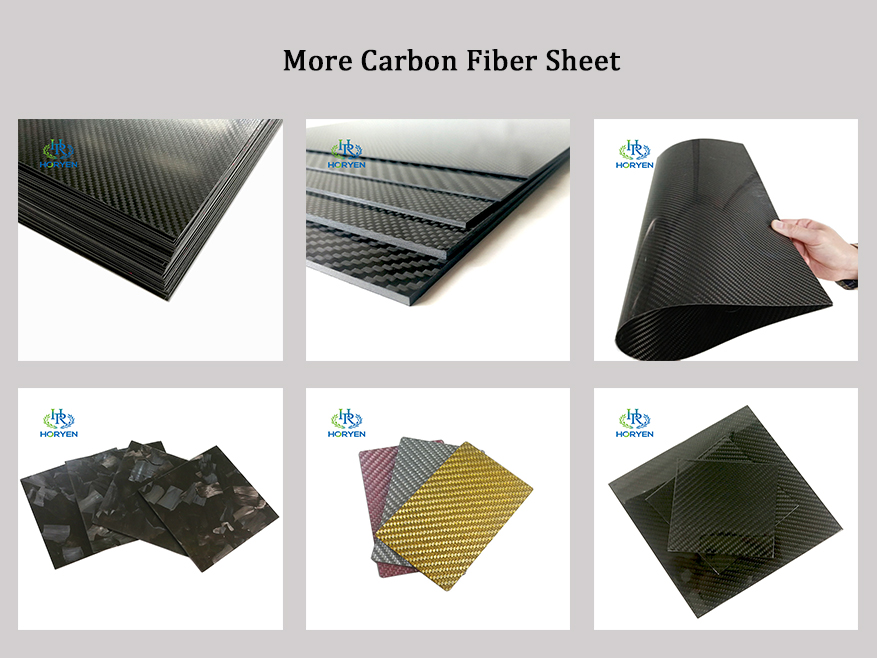

We also have Carbon Fiber Fabric,Carbon Fiber Tube and Aramid Fiber Fabric,so on.

| | Carbon fiber sheet | | | 400*500mm | | | 1mm,2mm | | | 100% carbon fiber | | | Forged | | | Glossy or matte | |

Feature:

1. high tensile strength and ray penetration

2. abrasion and corrosion resistance

3. high electric conductivity,soft and free to cut

4. light weight, easy to construct and little increasing the weight on constructed based materials

5. high elastic modulus

6. wide temperature range

7. good surface, factory price

8. other fabric area weight can be available

Our Advantages:

♦ Factory directly offer, competitive price

♦ Integrity management

♦ High-quality materials

♦ Timely delivery

♦ Offer processing service :punched, drilled, sawed, sheared

♦ Support small batch customization

♦ ODM/OEM/OBM service is accepted